Imagine your warehouse. What do you see? Tons of inventory, pallet rack after pallet rack? And what about all of the industrial equipment laying in the corner over there, taking up ample warehouse space?

Now look up. You see all that empty space up there? Wouldn’t it be great if you could build your storage areas upward and make use of all that open space? With Modula, you can.

Modula is a leading manufacturer of automated storage solutions, allowing businesses to design their warehouses vertically and utilize the full square footage of their facility. Additionally, Modula products streamline order picking, reducing the risk of human error and improving overall warehouse efficiency.

Keep reading to explore the following:

- What Does It Mean To Re-Space Your Warehouse?

- Best Modula Products for Re-Spacing

- What Are the Benefits of Re-Spacing Your Warehouse?

What Does It Mean To Re-Space Your Warehouse?

With Modula, re-spacing your warehouse is the process of recovering wasted floor space, maximizing payloads, customizing warehouse configuration layouts, and repositioning and rescaling warehouse layouts as needed.

Re-spacing your warehouse helps you and your workers get the most out of your warehouse setup, leaving space for open floor plans to scale with the growth of your supply chain.

Best Modula Products for Re-Spacing

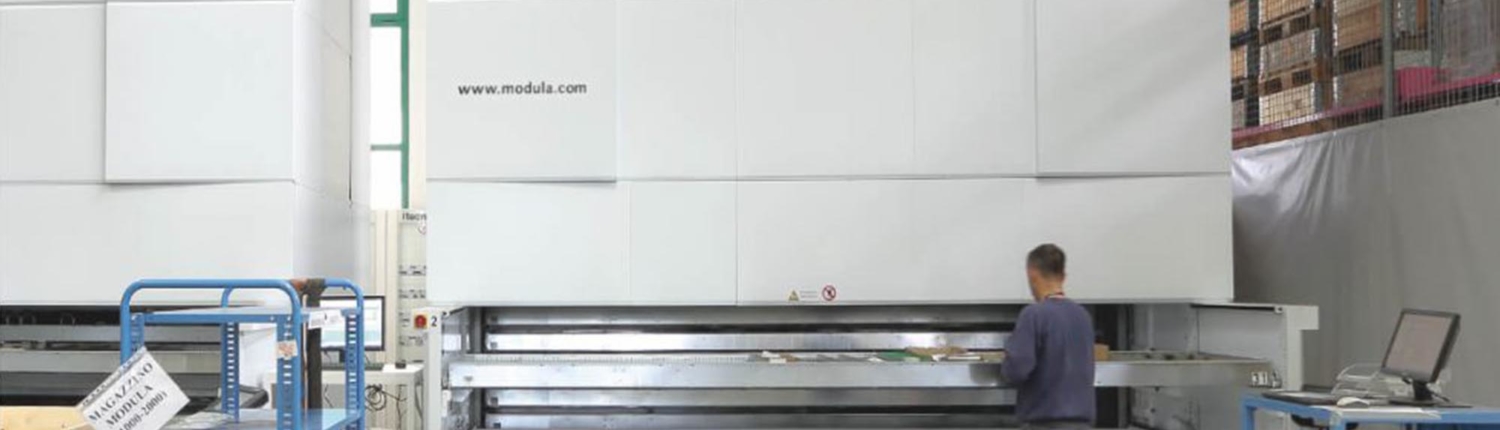

Modula Vertical Lift Module (VLM)

Modula’s vertical lift module (VLM) is a cutting-edge vertical warehouse solution that provides a cleaner and sleeker look while supporting a no-wasted floor space plan. This storage system is a one-of-a-kind solution that maximizes throughput and minimizes tedious employee tasks that are prone to human error. Other benefits of Modula’s VLM include:

- Enhanced speed and simpler order fulfillment

- Automated internal and external bays

- Real-time tracking information

- Streamlined communications

- Simplified stocking and reordering procedures

- Minimized risk of employee injury

- Improved security measures

Modula’s SLIM

Similar to the VLM, Modula’s SLIM takes a vertical approach when it comes to your warehouse configuration layout. However, Modula’s SLIM offers ample storage space with a smaller footprint than the VLM. This vertical warehouse system is essential for storing individual items, such as loose materials, small containers, spare parts, coils, bottles, etc.

A few key benefits of Modula’s SLIM include:

- Maximizing floor space

- Minimizing order picking times

- Improving operator accessibility

- Maintaining an appropriate amount of inventory

- Reducing picking errors

What Are the Benefits of Re-Spacing Your Warehouse?

Recovering Lost Floor Space

Are you looking to expand your warehouse operations, but don’t have any more room to install new machinery? With Modula, you have the opportunity to reduce your storage footprint with no wasted space floor plans.

Modula’s vertical storage products can reduce your storage footprint by up to 90%, giving you great room and ample space to implement other types of machinery that drive supply chain operations.

Warehouse Space Flexibility

Modula’s VLM is incredibly modular and adjustable to suit your warehouse configuration layout. This vertical storage solution can easily accommodate the space you have available, making it simpler to fit machinery as needed.

Additionally, the VLM’s structure can be modified according to item height, tray width, configurations, and accessories, making it one of the market’s most flexible vertical warehouse solutions.

Maximizing Payload Capacity

If you’re concerned that your old pallet racks can only hold so many more payloads, it may be time to consider your options. Modula’s re-spacing products, like the vertical lift module, can hold up to 1,600 pounds on each storage tray. However, this depends on which model you’re using, so it’s essential to consider your storage needs when choosing your vertical storage product.

With Modula’s automated height adjustment settings, you can use the full space of the machine. This leaves no wasted space between trays so you can store as many items as you need, no matter how wide or thin.

Ability To Reposition or Scale Your Facility

Expanding your warehouse or changing locations when business is booming can be time-consuming and negatively impact your bottom line. Modula’s vertical warehouse solutions can grow with your business, allowing you to adapt quickly and take advantage of the available vertical space.

Controlled Operations With a WMS

While we know you trust your warehouse workers to stay on top of everything, we also know how busy day-to-day operations can be, especially during peak seasons. Luckily, Modula’s vertical warehouse solutions are easily controlled with warehouse management systems (WMS).

A WMS is a centralized communication platform that brings all supply chain team members together, ensuring that high-demand inventory is stocked at all times. A WMS also automates tedious tasks so your workers can focus on more pressing responsibilities.

Improved Warehouse Sustainability

Modula’s vertical warehouse solutions may just be your answer if you’re looking for more sustainable warehouse operations.

With Modula’s warehouse configuration layouts, you minimize your equipment footprint and square feet of inventory storage areas. In doing so, you also reduce energy costs, develop more efficient warehouse processes, and create overall greener and cleaner operations.

Key Takeaways

In the beginning, we had you imagine your current warehouse configuration layout. Now that you’re aware of all the capabilities that Modula’s re-spacing products have, imagine your ideal warehouse space. Are you picturing a space full of Modula VLMs and SLIMs? Because we sure are.

Southwest Warehouse Solutions helps businesses across the West Coast get the most out of their warehouse space. As a growing warehouse solutions provider, we know how difficult it can be to maximize floor space and streamline processes while maintaining order throughput.

We’re proud to partner with Modula, a leading manufacturer of automated storage solutions.

When you’re ready to integrate Modula vertical warehouse solutions into your supply chain operations, contact the experts at Southwest Warehouse Solutions.